Providing Material Solutions For Your Creative Designs

Our textile product line offers a diverse and high-quality selection to meet the needs of different customers. Whether in design, functionality,

or manufacturing processes, our products are committed to providing the best options to meet the dual requirements of fashion and functionality.

Polypropylene Staple Fiber And Filament

In the field of polypropylene staple fiber and filament, we supply excellent quality long and short staple polypropylene fibers with outstanding physical and chemical properties. These materials are suitable for a variety of efficient and stylish clothing applications. We not only focus on the toughness and softness of the materials but also emphasize their plasticity and sustainability in the manufacturing process to meet the diverse needs of modern designs.

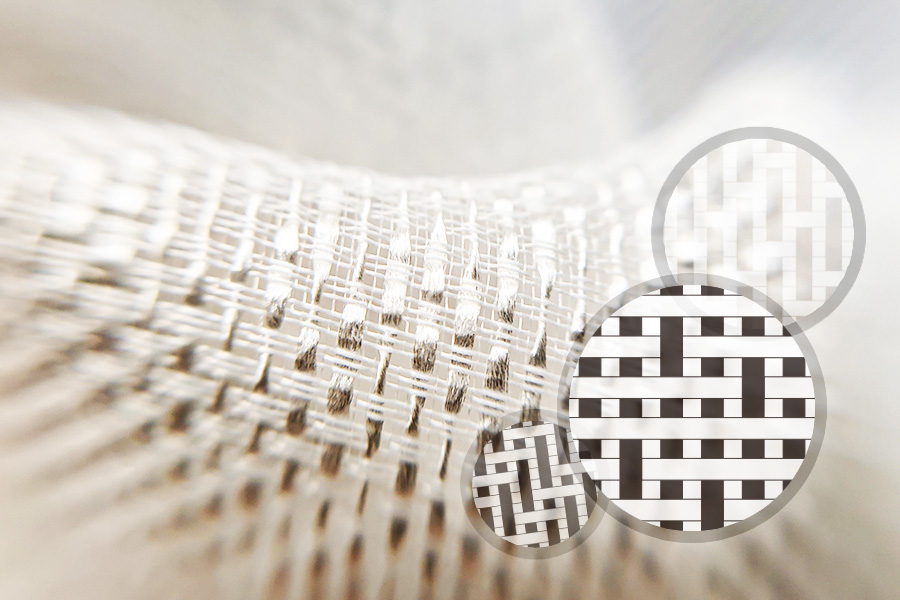

Polypropylene Fabrics

Our polypropylene fabrics are produced using highly technical knitting and weaving processes, offering a wide range of elastic and inelastic options. These products not only exhibit excellent durability and strength but also provide designers with greater flexibility in their designs. Through advanced processes, our fabrics achieve a high level of fineness and consistency, ensuring they meet the requirements of efficient and stylish designs.

Polypropylene Nonwovens

Our polypropylene nonwovens are produced using various advanced processes such as spunbond, SMS (spunbond-meltblown-spunbond), needle punching, and thermal bonding. These processes ensure the uniformity and structural integrity of the material, making it suitable for various garment applications. These polypropylene nonwoven products offer multi-level functionality, including but not limited to strength, breathability, and thermal insulation, to meet the diverse needs of different garment applications.

Polypropylene Accessories

H2L’s polypropylene accessories range covers elements such as yarns, zippers, bottom components, and buckles. These accessories not only possess excellent physical properties of polypropylene but also offer a diverse and comprehensive selection of garment accessories. Through these high-quality single materials, designers can unleash their creativity within the framework of sustainable development, creating unique and comprehensive fashion designs.

We Excel In Various Textile And Finished Product Manufacturing Processes, Constantly Pursuing Research To Advance In New Production Technologies.

We meet diverse customer demands for style, comfort, and innovation, showcasing our relentless pursuit of manufacturing craftsmanship and technological innovation.

Sewing

Sewing

Garments made with traditional lockstitch technology emphasize detail and exquisite craftsmanship.

Seamless by bonding technologies (non-sew)

Seamless by bonding technologies (non-sew)

Utilizing advanced bonding technology to achieve seamless designs, providing higher comfort and fashion.

Seamless By Electric Circular Knitting (Santoni)

Seamless By Electric Circular Knitting (Santoni)

Utilizing Santoni’s advanced digital circular knitting technology to achieve seamless production, injecting more flexibility and innovation into clothing.

Seamless By Flat Knitting (Shima Seiki)

Seamless By Flat Knitting (Shima Seiki)

Utilizing Shima Seiki’s advanced flat knitting technology to achieve seamless designs, creating a more unique and modern style of clothing.

Membranes And Water-Proof Protection (With Air-Permeability)

PP Microporous

A micro-porous film made of polypropylene (PP), providing superior breathability to regulate moisture while ensuring water resistance, offering excellent waterproof and breathable performance.

UHMWPE Microporous

A micro-porous film based on ultra-high molecular weight polyethylene (UHMWPE), known for its outstanding breathability and high molecular structural stability, providing excellent waterproof and breathable effects while maintaining durability.

Laminating And Coating

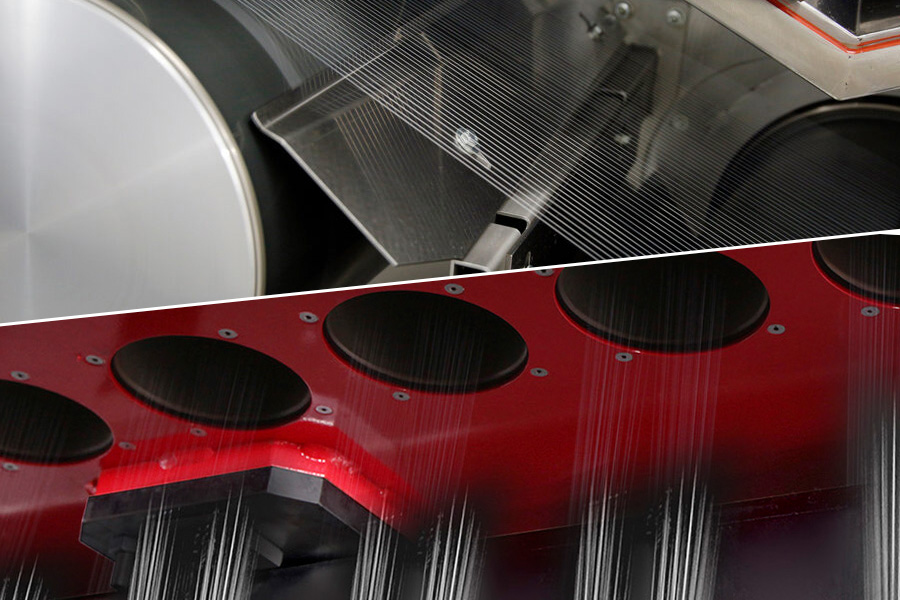

2 Layers / 3 Layers Lamination By Cavitec Lines

Using the Swiss Cavitec machine technology for 2- or 3-layer material lamination to effectively combine layers using advanced bonding methods to achieve desired performance and characteristics.

B-Component Coating

Complex reinforced coating technology enhances material properties like abrasion resistance, waterproofing, and weather resistance. It uses multiple chemical components and can be tailored to specific application needs.

Advantages Of Polypropylene

Polypropylene is a versatile material with several advantages compared to other plastics.

It has lower carbon emissions, is lightweight, quick-drying, offers superior insulation,

and has low allergenic properties. Its advantages include:

Low Carbon Emissions

Polypropylene has lower carbon emissions compared to polyester (one-third) and nylon (one-fourth), making it a low-carbon material.

Lightweight

With a density of less than 1, polypropylene is 35-45% lighter than polyester and 15-25% lighter than nylon, based on the same volume.

Low Allergenic Properties

According to the Environmental Protection Agency (EPA), polypropylene is safer than many plastics and does not contain Bisphenol A (BPA).

Chemical Resistance

It has excellent chemical resistance, able to withstand common chemical corrosion, making it perform well in various application environments.

Quick Drying

It maintains comfort and prevents prolonged moisture exposure.

Maintains Clothing Microclimate

Protects the body from external temperature influences.

Superior Insulation

With low thermal conductivity, it helps maintain temperature stability.